Solar for Shipping Containers

Introducing the latest option for mounting solar arrays to standard CONEX shipping containers. Our solar support structures enable 6-24 solar modules to be mounted on roof surface of standard 20-40 ft shipping containers.

Complete Solar Support Structures for Shipping Containers

-

Supports are made of 14 gauge galvanized steel

-

Support brackets use self-drilling screws into side of container

-

No roof penetrations to avoid leaks

-

Pro Solar rails system and module clamps

-

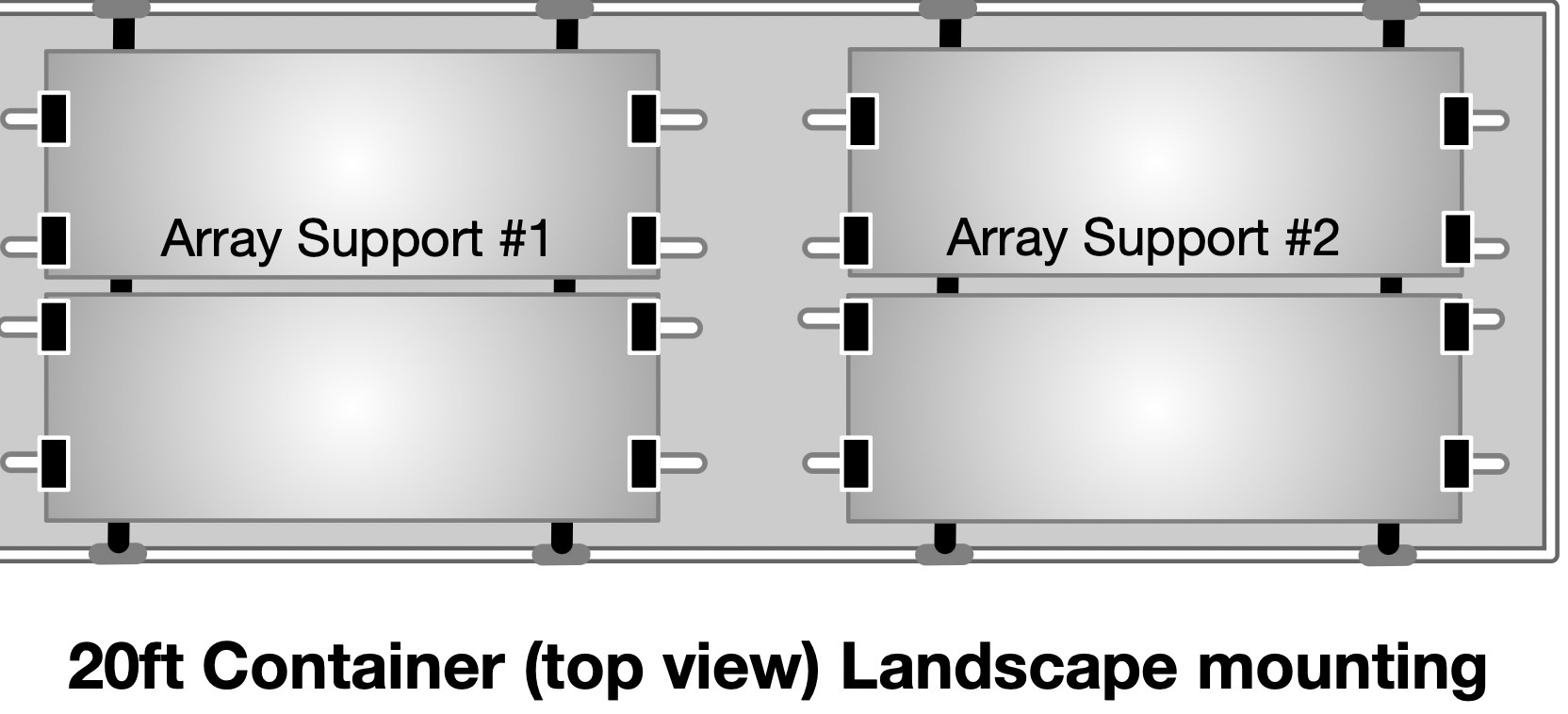

20ft container can hold two rows of six 40″ wide modules

-

40ft container can hold two rows of twelve 40″ modules

-

Site-Specific Engineering Available

Support frames attach to the container using leg foundations. These leg foundations attach to edge of container using self-drilling screws.

Example diagram of 20ft Shipping Container Solar

Supports can be picked up at the factory in full size. Alternatively the supports can be cut to smaller dimensions for shipment. User must then assemble using the splice inserts(provided).

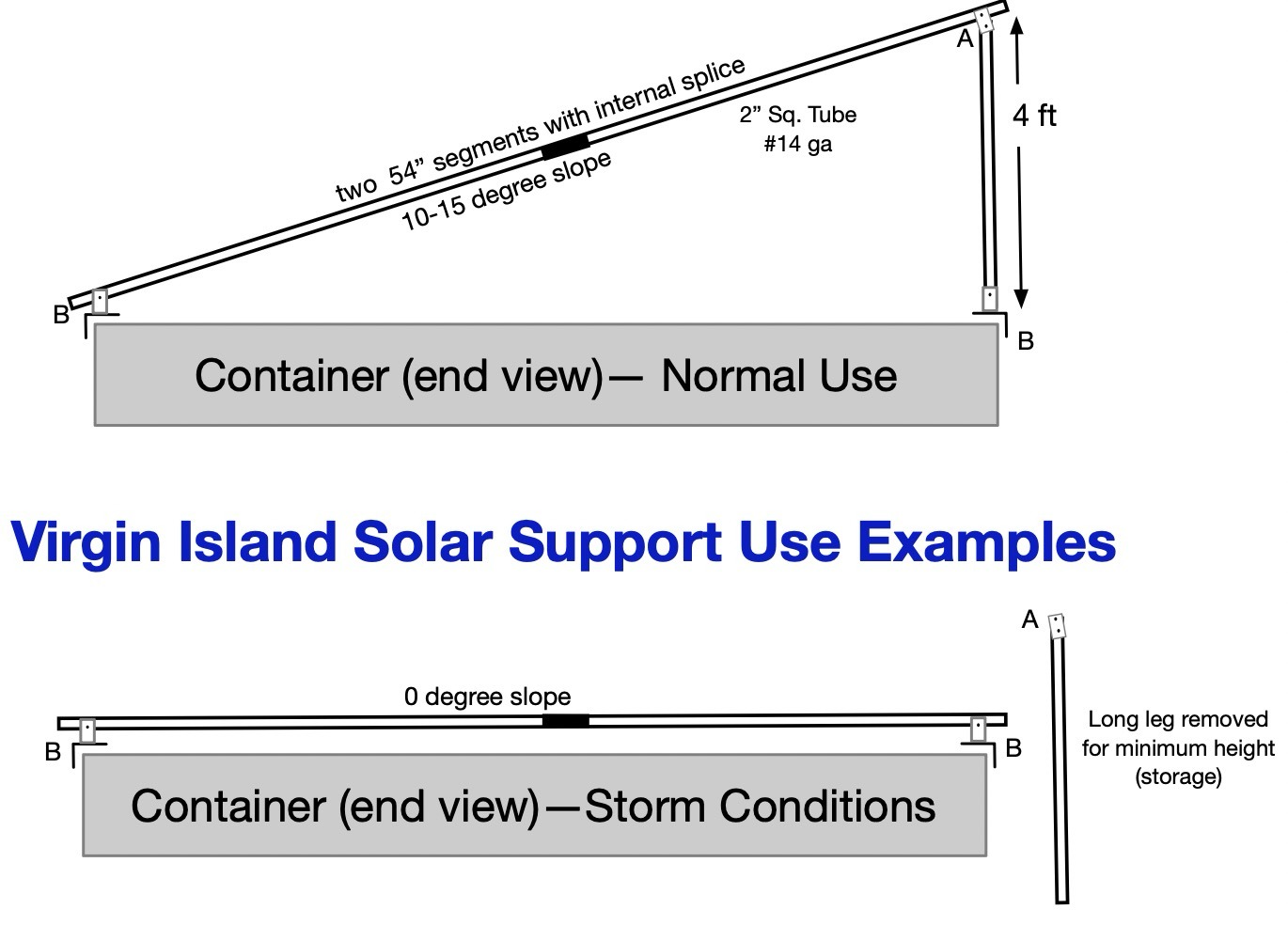

Solar Supports for High Wind Regions

Geographies that experience high speed wind events can benefit from our Virgin Island solar supports. These structures were designed in direct response to customer needs in the Virgin Islands. Structures provide normal tilted arrays, enabling maximum solar power harvest.

During storm season the solar supports can be temporarily lowered down to lie flat on the top of the shipping container. High side support legs can be removed using simple safety pins. Once pins are removed, the elevation legs can be removed, and pins are reinserted to secure the rails to the lower attachment brackets.

When in the stowed position, there is no overhang on any sides of the container in order to minimize wind resistance.

The structure is specifically engineered to resist corrosion in salt water exposure. Cross beams of the structure are galvanized steel. Brackets and roof attachments are made of stainless steel. Screws are stainless steel.

Virgin Island supports are sectioned for shipment as standard package delivery. Assembly requires a standard battery-powered screw gun.

FAQ’s

-How do the support attach? Support leg footers have holes to enable self-drilling screws to be installed in the sidewall edge vertical sides.

-Are there holes made in the roof? No, the screws only penetrate on the sides.

-Do the solar panels overhang the edges? It depends. If the array is large, the solar panels can safely extend beyond the roof edges by as much as 24-inches on all sides. Advise manufacturer if the solar panel dimensions are larger than the roof surface as longer rail segments may be required.

-What type of solar modules are recommended? Solar panels have two significant features that should be considered. One is the module frame thickness. The standard hold-down clamps are adequate for 30-40mm thickness. Secondly, solar panels can now be “bi-facial”. This means energy can be absorbed from sunlight hitting not only the top surface, but also from the backside. Bifacial panels will net 10-15% more energy harvest.

-Do I need engineering docs? It depends on your installation location and plans for building inspection. Engineering calculations can be created for a specific address in California for a fee. For other states, the engineering calcs can be performed, but will need to be stamped by a structural engineer in your state.